JFX200-2531 Serisi

Features of JFX200-2531

A choice of bed sizes and inks, including White and Clear, offers unlimited creative opportunities, with the capability to print to a wide range of substrates. Easy to use and with a compact footprint, the JFX200 Series maximizes productivity by providing the flexibility to use either one or two industry-standard sized boards, dependent on printer model.

Additional features of the JFX200-2531

Larger printing area enables printing up to 2.5 m × 3.1 m size

The larger print table is compatible with media as large as 2.5 m × 3.1 m. Moreover, the printer allows printing material as high as 50 mm and weight up to 50 kg/m2 to be used. Given its versatility and ability to handle large printing sizes and weights make the JFX200-2531 an evident choice for businesses that aspire to grow.

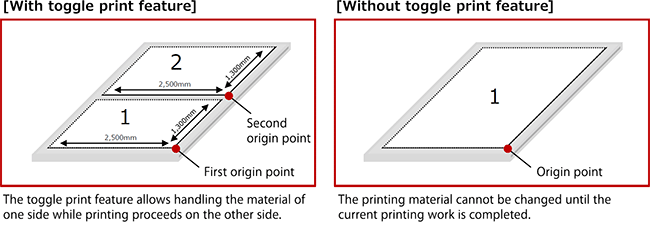

Toggle Print feature improves performance and productivity

The JFX200-2531 has the facility to set two separate printing origin points on the larger printing area of 2.5m x 3.1m. The Toggle Print feature allows the loading or unloading of print material on one side of the bed whilst simultaneously printing on the other side of the bed, providing considerable efficiency and productivity benefits.

The ionizer

The ionizer is a standard feature for eliminating the undesired electrostatic discharge that affects a printed image quality.

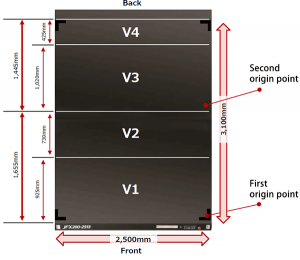

Divided suction vale

The printing material can be fixed onto the table using vacuum. Four suction areas are separately controlled by using valve switches. This capability improves the printing quality by providing stable media handling.

The printing material can be fixed onto the table using vacuum. Four suction areas are separately controlled by using valve switches. This capability improves the printing quality by providing stable media handling.

Click on image to enlarge it.

Vacuum pedal

This pedal allows operators to control the media vacuum power without the need to access the control panel at the front side.

Safety sensor

Safety sensors are installed at the front and back side of Y-bar. The printer stops operating when safety sensor is activated by obstacles. This function increases safety environment for operator.

JFX200 Series features

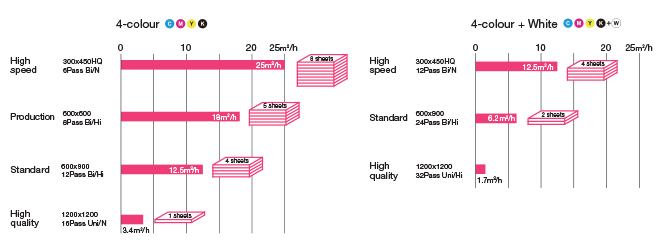

High Productivity and Print Speed

The Mimaki JFX200-2213 prints up to 8 sheets of 8ft x 4ft (2,440 x 1,220mm) media per hour.

Layout pins eliminate alignment problems

The JFX200 Series is equipped with pins and a scale to ensure accurate substrate alignment on the flatbed. By fixing the substrate to the pins, checking the placement against the scale and then editing the design data or printer setting accordingly, all alignment problems are eliminated.

Direct-to-media printing even on to thick media

Images can be printed directly onto rigid media up to 50mm thick, providing great versatility and a wider range of potential applications.

New Ink Supply Unit

Bottles of 1 liter ink can be easily inserted from the front of the printer, speeding up the replacement process.

Various ink types are offered for a range of materials and applications

A wide range of ink types is offered to accommodate the application needs.

- LH-100 ink: High scratch resistant ability.

- LUS-120 & LUS-150 inks: Suitable for printing on soft materials.

- LUS-200 ink: High weather resistant ability.

- LUS-350 ink (new): Thermoformable.

Core technologies of JFX200-2531

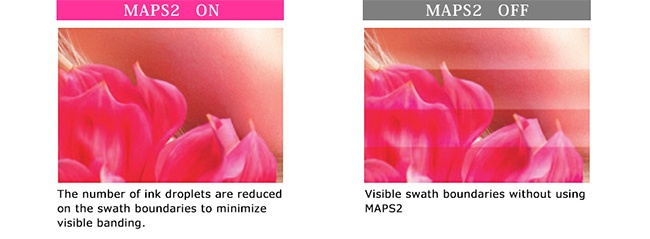

Mimaki Advanced Pass System (MAPS2)

Mimaki’s unique anti-banding feature, (MAPS2) is designed to prevent banding. Swath boundaries are overprinted and boundaries prone to banding are printed with fewer ink droplets.

Waveform control technique

Each ink color has its own specific gravity and viscosity. To achieve a precise placement of ink droplets onto the media, Mimaki has designed an optimum waveform control technique that allows the printhead to jet each ink color at an optimum angle, maintaining excellent ink droplet circularity. Thanks to precise ink droplet landing, three different droplet sizes are properly used for providing optimum print results.

Mimaki clear cont rol (MCT)

This technique adds a glossy finish on desired areas and a premium appearance to the print. However, clear-ink prints tend to be ruined by dusts adhering to uncured inks. In order to minimize dust adhesion and air bubbles on the print, MCC shortens the ink curing time by processing the clear ink print and UV-light irradiation simultaneously. MCC provides a gorgeous gloss finish and a stylish matte finish. Moreover, an embossed print is available by multiple applications of clear ink on specific areas; it adds a dimensional appearance to the print and enables representing the freshness of food or elaborate designs.

| Head | Staggered array of 2 heads | |

| Print resolution | 300, 450, 600, 900, 1,200dpi | |

| Ink | Type | LH-100 (C, M, Y, K, W, CI) LUS-120 (C, M, Y, K, W, Cl) LUS-150 (C, M, Y, K, W) LUS-200 (C, M, Y, K, W) LUS-350 (C, M, Y, K, W, Cl) Primer (PR-100, PR-200) |

| Ink supply system | Supplied from 1-litre bottles for each colour | |

| Ink circulation system*1 | White ink circulation using Mimaki Circulation Technology (MCT) | |

| Maximum media size | 2,500 x 3,100mm | |

| Media | Dimensions (W×D) | 2,500 x 3,100mm (or 2 x 1,220 x 2,440mm panels) |

| Height | 50mm | |

| Weight | 50 kg/m2 non concentrated load | |

| Media absorption | Absorption fixed through use of a vacuum | |

| Number of absorption area partitions | 4 partitions (X-axis direction) | |

| Range accuracy | Absolute accuracy | ±0.3mm or ±0.3% of the specified range, whichever is larger |

| Reproducibility | ±0.2mm or ±0.1% of the specified range, whichever is larger | |

| UV device | LED-UV system | |

| Standard service life*2 | Over 5,000 hours | |

| Interface | USB2.0 | |

| Safety standard | VCCI class A, CE Marking, CB Report, UL (U.S. safety organization), RoHS directive, UL 60950-1, FCC class A | |

| Input power supply | Single-phase AC200-240V 12A or less, 8A or less (Two inlets) | |

| Power consumption | 2.88 kVA, 1.92 kVA (Total: 4.8 kVA) | |

| Installation environment | Temperature | 15°C-30°C |

| Relative humidity | 35%-65% RH | |

| Accuracy maintained temperature | 18°C-25°C | |

| Temperature gradient | Up to ±10°C/h | |

| Dust | Similar to standard office environments | |

| Dimensions (W×D×H) | 4,400 × 4,290 × 1,250 mm | |

| Weight | 1000 kg | |